Environmentally Speaking

Package Dyed Fibers & Socks

Package Dyed Fibers & Socks

After they are extruded, most fibers used to knit socks are colored on dye cones or by placing socks in a dye bath. This is called package dyeing. Socks made this way are not 100% colorfast and bleed/fade faster. This process also requires additional energy to boil water to dye the fibers/socks which produces dye waste water. Work is being done to greatly reduce or eliminate the water needed for the package dye process. Some of our socks use package dyed yarns for our outer layer fibers.

drymax - Solution Dyed Fibers

drymax - Solution Dyed Fibers ![]()

drymax technology fibers are solution (dope) dyed where color pigments are added when extruded, locking in their pigments, producing colors that tend not to bleed/fade. After the fibers are made this dye process requires no additional energy and creates no dye waste water.

Staple Fibers/Yarns

Staple Fibers/Yarns

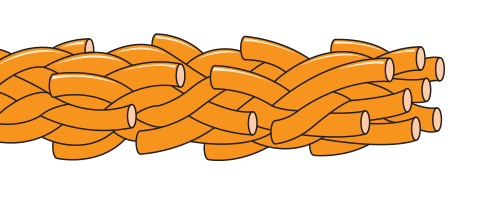

Many socks use manmade staple yarns which are shorter length fibers (1” to 2”) twisted (spun) together to make a yarn. Staple fibers feel soft to the touch, but easily shed making them weaker.

drymax Filament Fibers/Yarns

drymax Filament Fibers/Yarns ![]()

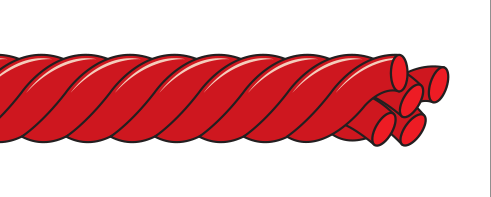

Filament yarns use long filament fibers from the start to the end of the sock. Filament fibers are stronger because they do not easily shed. We use filament yarns to help our drymax socks last longer. A product that lasts longer tends to be better for the environment.

The Deceptive Trick of Using Fabric Softener on Socks

The Deceptive Trick of Using Fabric Softener on Socks

Consumers often choose socks using their thumb & fingers to feel how soft the socks are. For this reason, some manufacturers coat their running socks with fabric softener, temporarily making much softer-feeling socks. Fabric softener is used to convince consumers to purchase their socks while their packaging cautions, “Do not use fabric softener”, even though fabric softener reduces the sock fibers’ effectiveness to move moisture. Fabric softeners are petroleum/silicone or lipid (fatty) substances that are not easily biodegradable and can irritate the skin. Once the socks are washed the softener and softer feel go right down the drain.

drymax Socks are Fabric Softener Free ![]()

We don’t use fabric softeners on our drymax socks because sock fibers need to be free of softener to work properly.

drymax socks are Race Ready right out of the package. Not using fabric softeners saves energy, creates less pollution and is less likely to cause skin irritations, it’s better for the environment and runners!

Laundry Fiber Pollution

Manmade plastic fibers being released from washing machines into our waterways and oceans have become a concern. It has been reported that microplastic fibers are being ingested by all types of marine life, including fish we eat. Look at the fibers that collect in the dryer lint tray. Washing machines, however, don’t have a trap to collect plastic fibers that shed from clothes. Further research needs to be done to better understand and eliminate this problem

![]() We believe using filament fibers/yarns as opposed to weaker staple fibers/yarns makes our products more resistant to shedding plastic fibers into the wash water and beyond.

We believe using filament fibers/yarns as opposed to weaker staple fibers/yarns makes our products more resistant to shedding plastic fibers into the wash water and beyond.

We didn’t turn green overnight; this is just what we do.